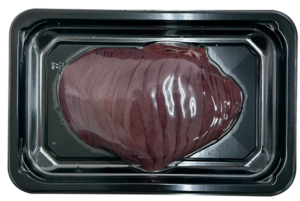

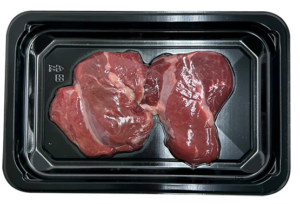

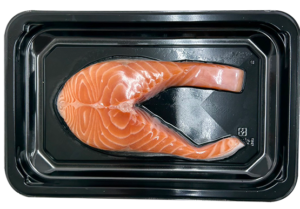

New trend of packaging – vacuum skin packaging

By sealing the product under vacuum between the skin packaging film and the tray. The VSP film wraps the food like a second skin without using any preservatives/additives. Make sure the product remains vibrant and fresh in color and flavor before consumption. VSP offers the added benefit of a reliable, durable tray that supports and protects the product during transport, storage and display as it holds food in place, with the ultimate goal of creating an attractive package that consumers can See the product in its entirety. The goal of VSP is to extend the shelf life of products.

Features

- It can optionally operate vacuum skin packaging. The super three-dimensional shape is transparent and visible.

- Sturdy structure and beautiful appearance, the whole machine is made of stainless steel and aluminum extrusion.

- Using European imported vacuum pump and programmable touch panel with 10 sets of memory functions, it can be used for vacuum nitrogen flushing, vacuum body-fitting and simple sealing packaging, easy to operate.

- Design different mold specifications according to product size, upper and lower molds can be replaced.

- Applicable to a variety of sealing materials, such as: PP, PE, PET, PVC, carton and other sealing materials.

Scope of application

- Suitable for refrigerated or seafood food, microwaveable, moisture-proof and takeaway food

- Suitable for restaurants, shops, supermarkets, processing plants

- Applied to fresh and frozen food such as meat and aquatic products, marinated food, agricultural products, prepared food, Chinese herbal medicine, electronics, medical equipment, medicine, etc., can keep fresh, original flavor, anti-corrosion, anti-mildew and deterioration, and extend product shelf life

Function

Keep food fresh, original, antiseptic, antiseptic, and extend product shelf life

| Model | Mechanical Dimensions (LxWxH mm) |

Voltage | Mechanical weight (kg) | Capacity (pcs/min.) |

container maximum size (mm) |

air compressor |

| EL-701VSP | 850 x 560 x 1555 | 220V | 120 | 2-3 | 340×250 | 5HP |

| EL-702VSP | 850x560x1555 | 220V | 145 | 4-6 | 220×170 | 5HP |

| EL-704VSP | 850 x 560 x 1555 | 220V | 145 | 8-12 | 160×100 | 5HP |

| EL-706VSP | 950x560x1555 | 220V | 150 | 10-12 | 110×100 | 5HP |

| EL-701MVSP | 900x600x1555 | 220V | 140 | 2-3 | 380×260 | 5HP |

| EL-702MVSP | 900x600x1555 | 220V | 160 | 4-6 | 260×180 | 5HP |

Automatic vacuum inflation and vacuum skin packaging machine

| Model | Mechanical Dimensions (LxWxH mm) |

Capacity (pcs/min.) |

container maximum size (mm) |

| EL-301VSP | 2000x810x1600 | 4-6 | 340×250 |

| EL-302VSP | 2000x810x1600 | 6-10 | 220×170 |

| EL-304VSP | 2000x810x1600 | 10-12 | 160×100 |

| EL-301MVSP | 2000x900x1600 | 4-6 | 380×260 |

| EL-302MVSP | 2000x900x1600 | 6-10 | 260×180 |

Video link

繁體中文

繁體中文 簡體中文

簡體中文 ру́сский язы́к

ру́сский язы́к