New trend of packaging – vacuum skin packaging

Vacuum skin packaging offers several advantages. First of all, it can effectively extend the shelf life of the product, prevent oxygen from entering the package, slow down the oxidation reaction and bacterial growth, and maintain the freshness and quality of the product. Secondly, vacuum skin packaging provides an excellent appearance display, and transparent packaging materials allow consumers to clearly see the product and increase purchase incentives. In addition, vacuum skin packaging can ensure the integrity and protection of the package, effectively preventing damage to the item during transportation and handling. At the same time, it is adaptable and can be applied to products of different shapes and sizes. In addition, vacuum skin packaging is simple to operate, easy to use and maintain. Finally, it also has environmental advantages, reducing the need for packaging materials. All in all, vacuum skin packaging is a packaging solution that extends shelf life, provides good presentation and protection, is adaptable and environmentally friendly.

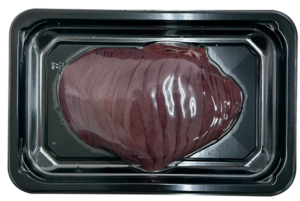

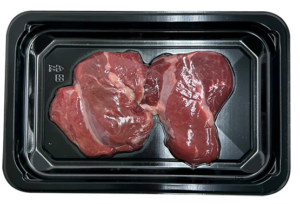

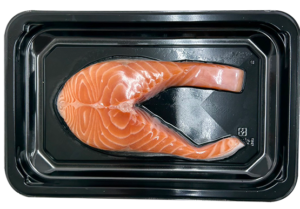

Application

The vsp machine is widely applicable to the package of raw and coinedmeat, seafood dairy product, fruit and vegetable,rice and flour food.

TECHNICAL CHARACTERS

- Stainless steel construction.

- Mold is available to be changed.

- Electronic temperature controller.

- Friendly and simply in operation foruser.

- Mold in customized dimension is acceptable to be made according to your own tray.

- Use European vacuum pump.

- The machine made in Taiwan.

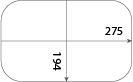

| Model | Max.width of film (mm) | Max.diameter of film(mm) | Capacity (box/hour)output | Vacuum pump(cam/hour) | Packing speed(cycle/min) | Electrical requirement(v/hz) | Consume power(kw) | N.w(kg) | G.w(kg) | Machine dimension(mm) |

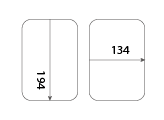

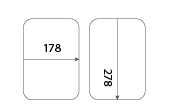

| EL-1250VSP | 250 | 180 | 320 | 10 | 2 | 220/50 | 1.2 | 36 | 40 | 510x350x400 |

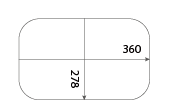

| EL-1320VSP | 300 | 180 | 320 | 20 | 2 | 220/50 | 1.6 | 56 | 68 | 590*450*400 |

EL-1250VSP

EL-1320VSP

繁體中文

繁體中文 簡體中文

簡體中文 ру́сский язы́к

ру́сский язы́к